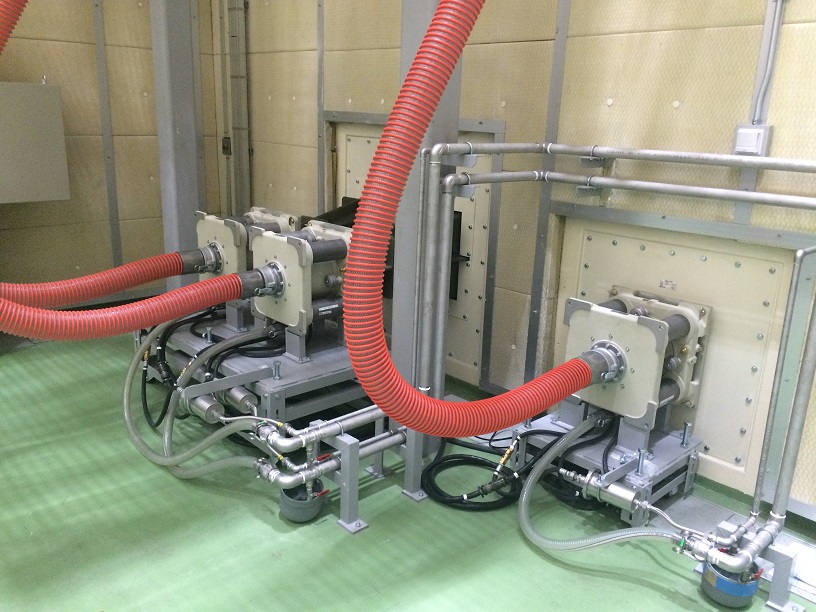

DTS Wide Band 10,000 Acoustic Watt Transducer

The EPT-200 modulator has been an industry standard in acoustic testing for over 40 years. We manufacture and stock the EPT-200 and all parts and accessories needed to support your acoustic testing needs. Parts and accessories include:

- EPT-200 Modulator

- Recommended Spare Parts

- Cooling Units and Field Supplies

- Cabling and Hoses

OEM SPECIFICATIONS:

Sine, Random and/or Complex Signals – DTS’s series of electro-pneumatic transducers provide a controllable method of generating high acoustic power levels by modulating a high volume, low pressure air flow. This method of high-intensity sound generation offers the user a choice of any input desired; it reproduce sine, random, speech or a combination of any or all.

Integral Air Filters – The EPT-200 has four self-contained air filters that may be easily removed for cleaning or replacement.

Cooling – The transducer uses a unique, high efficiency cooling system which is a key factor in its ability to generate high frequencies. The reciprocating valve assembly is cooled by a water spray. Water droplet and vapor are picked up using a high velocity vacuum system, carried to a separator/heat/exchanger and recalculated through the system. The driver coils are edge-wound conductors that are cooled directly by the same water spray. The field coils are made from hollow conductor that uses circulating water in a closed-loop cooling system.

Wide-Band Coverage – The EPT-200 uses a unique inductive drive system in the reciprocating valve assembly to achieve outstanding performance to frequencies considerably higher than previously attainable. The inductive drive requires no flexible leads or moving coil and offers maximum reliability and minimum moving mass through the use of a one-piece valve and single shorted turn. This design allows the valve to attain the extremely high acceleration levels necessary for operation at high frequencies. The reciprocating assembly is supported by rubber flexures which also act as diaphragm seals between the pneumatic pressure in the plenum housing and transducer cooling chamber.

Ease of Access – The exhaust plenum is held on with eight cap screws and is easily removed to expos the electro-magnetic structure and valve assembly for ease of maintenance and inspection.

ACOUSTIC/PNEUMATIC PROPERTIES:

Pneumatic Input: 1500 scfm @ 36 psig

Acoustic Power Output: 10 kilowatts

Air Pressure Required at Exhaust Plenum Hosing: 30 p sig (refer to graph)

Output Port Diameters: 3.57 inch Air Inlet Port: 4 inch quick disconnect fitting

Frequency Range: 0 to 5000 Hz

Maximum Allowable Plenum Pressure: 60 psig

Pressure Gauge Port: 1/4 inch Female NPT on exhaust plenum housing

Air Filtration: Internal filters provide 40 micron filtration

ELECTRICAL PROPERTIES:

Field Requirements: 1.4 kW

Driver Coil Requirements: 3.5 kVA

GENERAL:

Cooling System: External water and air system independent or primary air supply. Internal water filtration provides 40 micron filtration. Internal cooling air filters provide 40 micron filtration.

Position: May be operated in any orientation

Dimensions: 20” (508 mm) x 21” (533.4 mm) x 17.5″ (444.5 mm)

Weight: (less cables and hoses): 190 pounds (86.2kg)

OPTIONAL ACCESSORIES:

- P/N 35711 Transducer Mounting Plate

- 50, 100, 200 Hz Exponential Horns

- Single and Multiple Transducer Cooling Units

- Four-inch Air Hoses with Couplers

- Single and Multiple Transducer Field Supplies

- Model D12-x Power Amplifier

- Automatic Valve Bias Control Systems

- Motorized Valve Bias Control